Steel bar cutting machine

Introduction:

The steel bar cutting machine Model GQ40 is suitable for all kinds of carbon steel in reinforced concrete and hot-rolled round steel and rebar. GQ40 steel bar cutting machine can be also used to cut flat iron, square steel and angle steel.

Parameters:

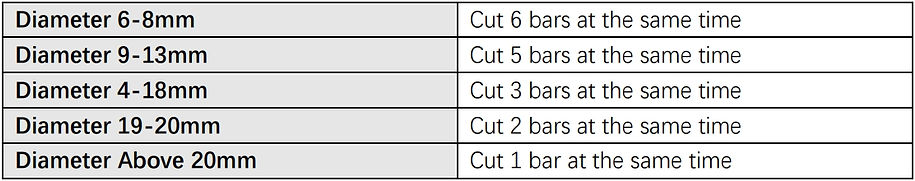

Recommended number of bars to be cut at the same time:

Full range models:

Features:

-

Small size, high quality, compact structure, reliable performance.

-

Good lubrication performance: it adopts box-type closed structure, gear splash lubrication, and it can continuous works more than 1 month after refueling. Notice: The oil level should not be lower than the oil scale line, so that the machine is always in good lubrication condition.

-

Less functional loss: due to the improved lubrication conditions, the gear shaft end adopts rolling bearings. Compared with the traditional steel bar cutting machine, the power can be reduced by 30%.

-

Easy to move: the front all-direction flexible wheels flexible, and easy to maintain.

-

Microcomputer control, automatic straightening, automatic sizing, and automatic cutting.

-

Easy operation, employees who understand "123" will be able to use it.

-

Multiple batches input length and quantity simultaneously, with computer storage and memory.

-

Hydraulic cutting, more accurate and quieter.

-

Small footprint, convenient for mobile installation.

-

Smooth operation, low failure rate, easy maintenance, and cheap accessories.

-

This machine is equipped with high-quality components, heavy casing, heavy-duty pulley<70 pounds, thickened side cover, using a grease adjusting crankshaft, grease adjusting crankshaft wheel, equipped with a blade holder, weighted connecting rod, copper curved bearing, national standard 3kw line motor, fully enclosed cover, rigid clutch shaft sleeve, weighted casters, thickened upper cover plate with toolbox, 20a Delixi Electric with thermal relay, high-quality triangular belt, high-quality bearing, thickened blade, thickened pressure blade plate, high-quality cutting blade, and dual use clutch rod with chrome plating.

Notes:

-

After starting, the machine should be idle first, and all transmission parts and bearings should be checked for normal operation before operation.

-

When the machinery has not reached the normal speed, it is not allowed to cut materials. When cutting, the middle and lower parts of the cutting blade should be used, and the steel bar should be tightly grasped and aligned with the blade edge to quickly insert. The operator should stand on the side of the fixed blade and press the steel bar firmly to prevent the end of the steel bar from popping out and injuring people. It is strictly prohibited to use both hands to hold the steel bars on both sides of the blade and bend down to feed.

-

Do not cut steel bars with diameters and strengths exceeding those specified on the mechanical nameplate, as well as steel bars that have been burned red. When cutting multiple steel bars at once, the total cross-sectional area should be within the specified range.

-

When cutting low alloy steel, the high hardness cutting blade should be replaced, and the cutting diameter should meet the requirements of the mechanical nameplate.